Automatic Printed Sheet Position Thermoforming Machine

SL-480F/540F Automatic Printed Sheet Position Thermoforming Machine, is specially designed by our professional technical teams according market demand and conventional production technologies.

online service

Tel:+86-577-65012596

Email: info@shunlongpack.com

Skype: +8615325077939

Whatsapp/Wechat/Viber: +8615325077939

Briefly Introduction

SL-480F/540F Automatic Printed Sheet Position Thermoforming Machine, is specially designed by our professional technical teams according market demand and conventional production technologies. This machine is our innovative new product in the market! The machine is a multi-station automatic thermoforming machine, complete with a synchronous printed sheet roll servomotorfeeding, heating, forming, hole punching, cutting, stacking, which solves the food packaging sanitation problem. It not only effectively solves the printed PS / PET / PVC and other plastic products production issue “high capital investment, labor input large, complex production processes, product safety and low health problems”, but also has a wide range of usages: such as hardware tool, food, pharmaceutical etc upscale blister packagers. This machine appearance is good, reasonable price, Domestic and foreign users welcome!

Usage:

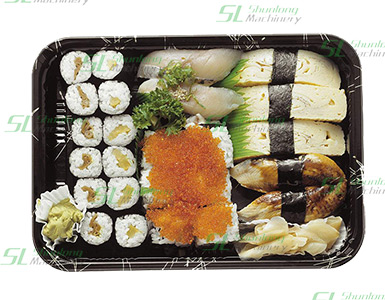

This machine is mainly used for thermoforming printed blister packagers for packing chocolate, candy, toys, food etc. For example, kinder joy egg shell, Sushi printing tray, printed cup lid, 3D cartoon characters, Cartoon mask etc, also used for non-printing plastic sheet thermoforming: for example, hot drinking HIPS coffee cup lid, cold drinking PET cup lid,HIPS spoon, plastic dish, food tray, electronic trays and various shapes of plastic products.

Main Futures:

1. This machine could achieve GMP / QS dual standard clean production, improve product health and safety and solve cross-contamination.

2. Adopts sheet roll servo feeding, heating, molding, hole punching, cutting,scrap rewinder, finished products transmission automatically. Servomotor feeding, which is more precise, compact structure, smooth operation, simple operation and so on.

3. Adopts special aluminum plate touch heater, which could save

4. The journey of this machine is adjustable, and easy to change the molds for different sizes of products.

5. This machine adopts PLC and Touch Panel control, inverter speed control.

6. The Molds could be specially designed according to customers’ request.

Main Technical Parameter:

|

Model |

SL-480F |

SL-540F |

|

Running Speed |

10-30 cycles/min |

10-30 cycles/min |

|

Max. Forming Area |

480x250mm |

540x320mm |

|

Max. Forming Depth |

50mm |

80mm |

|

Stroke |

40-250mm |

40-320mm |

|

Servo Feeding Motor |

1.5KW |

1.5KW |

|

Air Pressure |

0.4-0.6MPa |

0.4-0.6MPa |

|

Air Consumption |

0.3m³/min |

0.3m³/min |

|

Heating Power |

2.5KW*3pcs=7.5KW |

3KW*3pcs=9KW |

|

Driving Method |

Main Motor 2.2KW |

30 Ton Pressure Pneumatic Cylinder |

|

Lower Film Material (Rigid Film) |

PVC/PET/PS Sheet: 0.2-0.55mmX480mm |

PVC/PET/PS Sheet: 0.2-0.6mmX540mm |

|

Voltage |

3P, 380V/50HZ |

3P, 380V/50HZ |

|

Dimension |

3500x820x1600mm(L/W/H) |

3560x870x1700mm(L/W/H) |

|

Weight |

1200kg |

2000kg |

Welcome to our website! Please send your words at any time in the following form and ask us, we will contact you and provide you with the corresponding service as soon as possible. Please write in English.

Disposable Plastic Cup Production Line

The complete production line mainly includes plastic sheet extrusion line, plastic cup making machine, molds, cup stacking machine, plastic crusher, plastic mixer, cooling chiller, air compressor and etc.

Learn MoreAutomatic Printed Sheet Position Thermoforming Machine

SL-480F/540F Automatic Printed Sheet Position Thermoforming Machine, is specially designed by our professional technical teams according market demand and conventional production technologies.

Learn More